CNC Services Leicester

At Precision Engineering UK Ltd, our CNC services represent the cutting edge of modern manufacturing technology. Computer Numerical Control allows us to produce components with exceptional accuracy, repeatability and outstanding efficiency.

Our investment in advanced CNC equipment, combined with skilled programming and operation, enables us to tackle challenging projects that demand the highest levels of precision.

Request A Quote

Request A Quote

CNC Milling

CNC milling uses computer-controlled cutting tools to remove material and create precise shapes, profiles and features.

Our CNC milling capabilities span from straightforward two-dimensional profiles to intricate three-dimensional forms with complex geometries.

The computerised control system follows exact tool paths, producing components with tight tolerances and excellent surface finishes. This technology excels at creating parts with pockets, slots, contours and detailed features that would be extremely difficult or time-consuming using manual methods.

We can mill a diverse range of metals and plastics, with the CNC process particularly suited to materials like aluminium, stainless steel and tool steels where dimensional accuracy is critical.

The repeatability of CNC milling makes it ideal for producing multiple identical components, whilst the flexibility of programming means we can quickly adapt to design changes or produce small quantities economically.

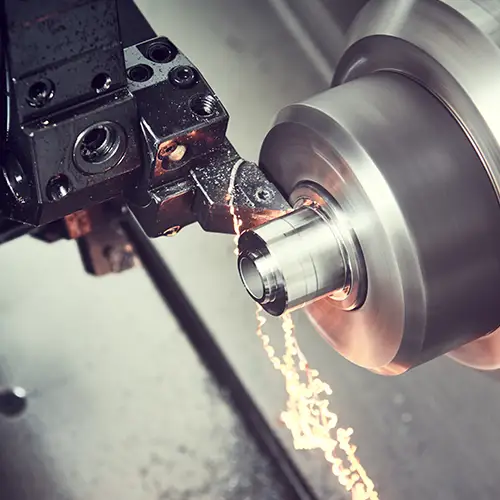

CNC Turning

CNC lathes rotate the workpiece whilst computer-controlled cutting tools shape cylindrical and conical forms with remarkable precision.

Our CNC turning services produce shafts, bushings, pins, hubs and other rotational components to exacting specifications. The automated nature of CNC turning delivers consistent diameter control, precise thread cutting and accurate facing operations across entire production batches.

Complex turned components featuring multiple diameters, grooves, tapers and threaded sections can be machined in a single setup, reducing handling time whilst maintaining accuracy.

The technology handles both external turning operations and internal boring work, creating components from solid bar stock or pre-formed materials.

CNC turning particularly benefits projects requiring numerous identical parts, as the programmed tool paths guarantee every component matches the first, eliminating the variation that can occur with manual turning.

Request A Quote

Request A Quote

Request A Quote

Request A Quote

CNC Machining

Our broader CNC machining capabilities integrate milling and turning operations to manufacture sophisticated components requiring multiple processes. Complex parts often need both rotational features and flat surfaces, slots or holes - operations that CNC technology can combine efficiently.

The precision positioning systems within CNC machines work to tolerances measured in thousandths of a millimetre, creating parts that fit together perfectly in assemblies.

Modern CNC equipment can hold these tight tolerances consistently throughout production runs, whether we're making five components or five hundred.

Quality control is built into the CNC process, with digital measurement systems and proven programs reducing the possibility of human error.

This technology opens up design possibilities that simply weren't practical with conventional machining, allowing our engineers to specify features and geometries that optimise product performance.

CAD/CAM Services

We offer CAD/CAM services to support the entire CNC manufacturing process. Computer-Aided Design and Computer-Aided Manufacturing technology forms the bridge between concept and finished component.

Our CAD/CAM capabilities mean we can work from your technical drawings, convert designs into machine programs, and optimise tool paths for efficient production. If you're developing a new product, we can assist with design refinement to make components more manufacturable whilst maintaining functionality.

The CAD/CAM process allows us to simulate machining operations before any metal is cut, identifying potential issues and perfecting the approach. This digital workflow speeds up the journey from design to production, reduces development costs, and helps achieve first-time success with new components.

Request A Quote

Request A Quote